A new state-of-the-art scientific instrument arrives in Grenoble

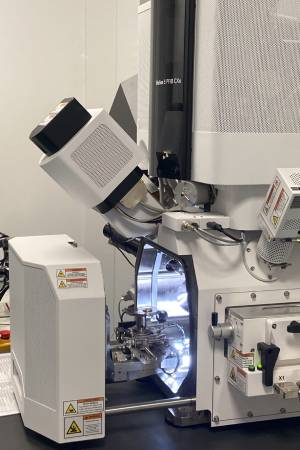

A latest-generation PFIB-SEM,* funded by Grenoble INP-UGA and the French Alternative Energies and Atomic Energy Commission (CEA), has been inaugurated in Grenoble.

Traditionally used in the semiconductor industry, FIB-SEMs are seldom found in academic institutions and those based on plasma technology, as is the case with this new acquisition, are even rarer still. This instrument replaces the now obsolete device purchased in 2009 via the Nanosciences Foundation, and reinforces Grenoble INP-UGA's collaboration with the CEA on this technique.

At the end of 2022, a state-of-the-art PFIB-SEM was installed on the Nanocaracterisation Platform (PFNC) at the CEA centre in Grenoble. Half of its total cost of €1,032,000 was funded by the CEA and the remainder by Grenoble INP-UGA, with support from Labex CEMAM (Centre of Excellence for Multifunctional Architectured Materials).

Rarely encountered in academic environments, this scientific instrument combines a focused ion beam (FIB) with a scanning electron microscope (SEM) to enable the etching of matter at an accuracy exceeding 10 nm. In this case, a new xenon plasma technology replaces the formerly used gallium-ion-based system. "The new plasma technology increases ion abrasion speeds by up to a factor of 20 compared with a traditional gallium FIB, while limiting the phenomenon of ion implantation", explains Laurent Maniguet, Director of the CMTC** platform. “In practical terms, this means we can obtain cuts measuring several tens of microns across in a matter of minutes." The device can be used as a nanometric scalpel to incise matter, combined with an electron microscope to observe its properties. A wide range of applications

A wide range of applications