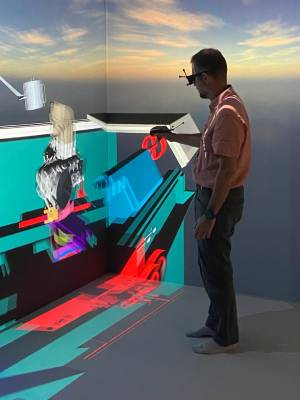

A corner CAVE (Cave Automatic Virtual Environment) has been acquired as part of the EquipEx* Continuum, a national infrastructure project bringing together 22 partners whose equipment is networked for collaborative use.

Also known as an immersive cube, the CAVE consists of walls, a floor and sometimes a ceiling, which are used to project images and behave like very large screens. The new equipment acquired by Grenoble INP – UGA as part of the EquipEx Continuum consists of a floor and two image walls 4m x 4m x 3.20m. In reality, these surfaces are stereoscopic back-projection screens, which display light coming from projectors located behind them, a video sequence making it possible to recreate an immersive virtual environment. The images are of the same nature as those projected in cinemas equipped with 3D technology. The movements of the user placed at the heart of the space are captured so as to synchronise them with different points of view in the video sequence displayed on the screens. A cluster of networked PCs processes the images in real time in order to obtain excellent visual quality.

The new equipment is installed in a dedicated room that was refurbished during the renovation of the Viallet site as part of the A2i project, and completes the Vision-R platform, which already brings together equipment from the G-SCOP research centre** shared in the context of the S.mart Grenoble Alpes Technological Centre***: there is already a mini CAVE, a video mapping room, etc. “EquipEx has made it possible to finance the upgrading of our virtual reality room by investing in a big CAVE”, explains Frédéric Noël, lecturer at Grenoble INP – Industrial Engineering and researcher at G-SCOP. “This facility will be used collaboratively thanks to the networking of Continuum members’ equipment”, spread across France. In Grenoble, the Continuum project has two partners in addition to Vision-R: Université Grenoble Alpes’ Inria Centre’s Kinovis platform and LIG’s Playground platform****.

Above all a research tool but also a teaching facility and a support for industrial partnerships

Started two years ago for an eight-year period, the Continuum project is still in its installation phase, before the actual use begins. Researchers will then have the task of developing collaborative use of the facility in order to optimise the remote 3D immersion experience. They must also perfect Human-Computer Interfaces (HCI) and develop video content depending on the envisaged use for industrialists and researchers from other units who may be interested.

At the Viallet site, these uses are naturally associated with professional applications from the manufacturing industry: support for design, manufacture, maintenance, monitoring of industrial flows and collaboration between key industrial players. Manufacturers contact the research centre for partnerships, to test and bring into use this type of equipment, to train their personnel or to investigate, test and compare emerging technologies that they are considering deploying in their processes. “However, visualisation and interaction technologies open up a wide range of applications in which we are also sometimes involved: pure science, heritage, the arts, health, etc.”, says Noël. “This can produce applications for museums, for example, or in the health sector. For example, we have an ongoing project with Grenoble physiotherapy school to teach students to find the right points of interest on ‘augmented’ real patients. But one can also imagine lots of other scenarios, depending on users’ needs. We are also involved in the CHRONOSPEDIA project, which aims to create an encyclopaedia of clock-making expertise.”

As a member of the future national Continuum infrastructure, Grenoble’s CAVE will receive academics and industrialists from elsewhere to work either independently or in collaboration with other immersive cubes. “We can receive scientists who want to view samples of material in 3D at a large scale and we are developing projects to control digital twins for various systems, from machine tools to satellite constellations.” Finally, although EquipEx projects finance equipment devoted to research into the subjects covered by the relevant research units, they also contribute to teaching activities with local training courses. The Grenoble CAVE will also be used for practical work by students at Grenoble INP - Industrial Engineering, the University Institute of Technology, Mechanical and Production Engineering and other interested courses.

Continuum’s scientific objectives

Continuum aims to create a “collaborative continuity from the digital to the human” by developing interdisciplinary research at the interface between computing and human and social sciences. The project brings together equipment such as huge screen walls, immersive rooms and virtual or augmented reality headsets spread over 30 platforms. This equipment is used to visualise complex scientific data, to create virtual environments, for example to study or cure phobias or to design historical reconstitutions. There are 22 partners including the CNRS, which oversees the project, the CEA and Inria, but also ten universities and nine graduate schools.

* EquipEx: project to provide structuring equipment for research / Continuum: collaborative continuity from the digital to the human

** CNRS, Grenoble INP – UGA, UGA

*** The S;mart Grenoble Alpes technological centre includes five technological platforms on the Viallet site built around the product life cycle, from creation of a solution to the end of the product’s life. Vision-R is one of these five platforms.

**** CNRS, Inria, UGA, Grenoble INP – UGA