Etienne Perret is no stranger to awards and distinctions. In addition to an Académie des Sciences prize in 2020, he was awarded a prestigious ERC grant in 2018. He received this grant for his method of capturing information based on the principle of reflectometry and the use of resonant elements that he developed in the laboratory. After four years of development, the project has come to fruition, and Perret has now been awarded an ERC Proof of Concept grant to explore the commercial and societal potential of his work.

The technology developed by Etienne Perret has given rise to chipless identification tags that are printable, recyclable and inexpensive. Unlike barcodes, they can be read through opaque objects and at very high speed. What’s more, because they don’t contain a chip or antenna, they are much cheaper than RFID tags.

The only difference between these chipless RFID tags and barcodes is their shape and the use of conductive ink deposited during printing. Each tag, created separately or printed directly on the product to be identified, has an electromagnetic signature containing information specific to the product. “The conductive ink interacts with the wave that is sent to the tag,” explains Etienne Perret.

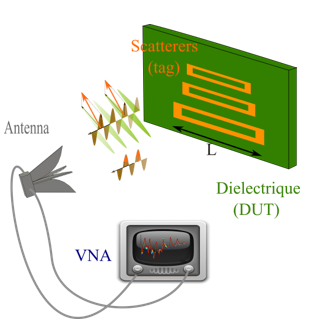

“The information contained in the specific signature of the reflected wave is recovered by a sensor.” The scientist’s work consisted in perfecting the method used to size and design the labels according to the information to be included. As well as being inexpensive and flexible in terms of reading, these labels can be rewritten, making them very different from barcodes in terms of application.

Dielectric characterisation

As part of his 18-month ERC PoC, Etienne Perret will be studying the potential of this method for characterising dielectrics. These non-conductive materials are used in many fields (electronics, aerospace, defence, etc.), and need to be accurately characterised according to their intended application. However, the measurement of their electrical properties (permittivity and dielectric losses, in particular) is usually carried out using very expensive specific equipment, and requires a good knowledge of radio frequencies.

“We were able to show that there was a very simple way of accessing these measurements, based on the principle of the previous project: we use a kind of tag, to which we send a wave. The reflected wave provides information about the characteristics of the material on which it has been placed. This is what we are seeking to demonstrate over a wider range of applications, in particular by attempting to extend the field of study to liquid and powder dielectrics.” In addition to the characterisation method, Etienne Perret and his team at LCIS also developed the measuring device, which was transferred to Idyllic Technologies.

* UGA, Grenoble INP - UGA, ANR, Région AuRA

Etienne Perret is no stranger to awards and distinctions. In addition to an Académie des Sciences prize in 2020, he was awarded a prestigious ERC grant in 2018. He received this grant for his method of capturing information based on the principle of reflectometry and the use of resonant elements that he developed in the laboratory. After four years of development, the project has come to fruition, and Perret has now been awarded an ERC Proof of Concept grant to explore the commercial and societal potential of his work.

Etienne Perret is no stranger to awards and distinctions. In addition to an Académie des Sciences prize in 2020, he was awarded a prestigious ERC grant in 2018. He received this grant for his method of capturing information based on the principle of reflectometry and the use of resonant elements that he developed in the laboratory. After four years of development, the project has come to fruition, and Perret has now been awarded an ERC Proof of Concept grant to explore the commercial and societal potential of his work.