Radio frequency identification (RFID) is a method to remotely save and recover data using RFID tags. The researchers at LCIS came up with the idea to use this technology to create passive and wireless identifiable sensors.

In this respect, there are many advantages to the RFID tags composed of an antenna associated with an electronic chip allowing them to receive and respond to radio frequency requests issued from a transceiver called a “reader”. Firstly, they are passive devices that do not require any energy source apart from that supplied by the reader upon interrogation. Secondly, the communication protocols between the reader and the label are standardised and enable the use of several tags at the same time. Thirdly, at present, chips can be read from hundreds of meters away thanks to the technology used in the active tag based systems (tag in which an energy source is embedded).

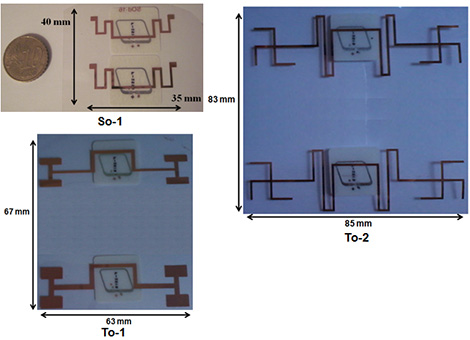

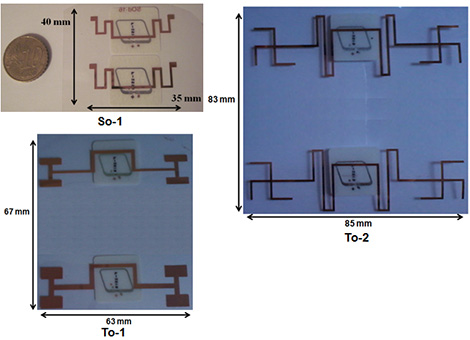

“In order to transform the tag into a sensor, we adjust the antenna which is very sensitive to its nearby environment, explained Smaïl Tedjini, a researcher at LCIS. Let us take for example an antenna designed in a material with a high expansion coefficient and which is therefore sensitive to temperature: in this case, the resonance frequency will vary depending on the length of the antenna, making it possible to indirectly measure a temperature.” Moreover, it is possible to combine several sensors to access other parameters such as the speed of revolution. “To this end, several sensors must be positioned appropriately with respect to each other. In this way, a fixed sensor compared with a mobile sensor will vary the signal amplitude periodically and thereby help to calculate the speed of revolution.”

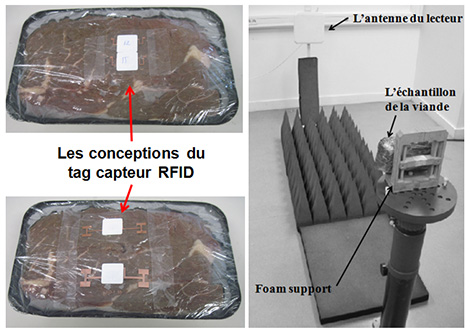

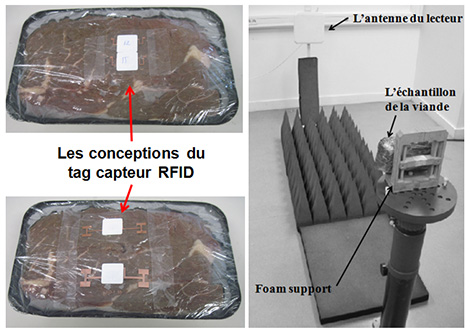

This technology has already been used by the Valence-based laboratory to quantify humidity rate and to deduce the coolness of meat. Within the context of the Innov’Hydro project, it will be used in particular to measure the speeds of revolution in hydraulic turbines.

In this respect, there are many advantages to the RFID tags composed of an antenna associated with an electronic chip allowing them to receive and respond to radio frequency requests issued from a transceiver called a “reader”. Firstly, they are passive devices that do not require any energy source apart from that supplied by the reader upon interrogation. Secondly, the communication protocols between the reader and the label are standardised and enable the use of several tags at the same time. Thirdly, at present, chips can be read from hundreds of meters away thanks to the technology used in the active tag based systems (tag in which an energy source is embedded).

“In order to transform the tag into a sensor, we adjust the antenna which is very sensitive to its nearby environment, explained Smaïl Tedjini, a researcher at LCIS. Let us take for example an antenna designed in a material with a high expansion coefficient and which is therefore sensitive to temperature: in this case, the resonance frequency will vary depending on the length of the antenna, making it possible to indirectly measure a temperature.” Moreover, it is possible to combine several sensors to access other parameters such as the speed of revolution. “To this end, several sensors must be positioned appropriately with respect to each other. In this way, a fixed sensor compared with a mobile sensor will vary the signal amplitude periodically and thereby help to calculate the speed of revolution.”

This technology has already been used by the Valence-based laboratory to quantify humidity rate and to deduce the coolness of meat. Within the context of the Innov’Hydro project, it will be used in particular to measure the speeds of revolution in hydraulic turbines.

SUMMARY

- Imagining the hydraulic machines of the future

- Hydroelectricity: an energy of the future

- Innov'hydro: a multi-disciplinary project

- "We will not be the best on our own"

- Tidal turbines in rivers and at sea

- LCIS transforms RFID labels into sensors

- Micro hydropower plants to provide rural areas with electricity