Contents

15 Years of Education to Connect Physics and Biology

15 Years of Education to Connect Physics and Biology

Physics in the Service of Life Sciences

Physics in the Service of Life Sciences

The Power to Heal Bones

The Power to Heal Bones

Intelligent and Biocompatible SiC

Intelligent and Biocompatible SiC

The Secret Virtues of Hemicellulose

The Secret Virtues of Hemicellulose

Improving the Stability of Therapeutic Proteins

Improving the Stability of Therapeutic Proteins

Growing Micro-Muscle Tissue

Growing Micro-Muscle Tissue

A Bio-Battery to Power Artificial Organs

A Bio-Battery to Power Artificial Organs

15 Years of Education to Connect Physics and Biology

15 Years of Education to Connect Physics and Biology

Since the 1970s, the CEA and other major research institutions in Grenoble have attracted numerous biophysicists. But it was not until the beginning of the 21st century that a biology program was offered as part of Grenoble INP-Phelma, the university's school for physics. The school's dean at the time, Claire Schlenker, launched a specialized program based on biotechnologies in order to meet increasing demands from companies and laboratories.

Since the 1970s, the CEA and other major research institutions in Grenoble have attracted numerous biophysicists. But it was not until the beginning of the 21st century that a biology program was offered as part of Grenoble INP-Phelma, the university's school for physics. The school's dean at the time, Claire Schlenker, launched a specialized program based on biotechnologies in order to meet increasing demands from companies and laboratories.As the uses for technology in biology and health continue to expand, the school's Biomedical Engineering program now trains approximately 50 students per year. The program is also tied to the Life Sciences master's offered by the University Grenoble Alpes (UGA). Starting in 2016, students in the program will receive a dual degree from Grenoble INP and UGA (the Nano-Biosciences master's or the Nano-Biomedicine and Structural Biology master's).

Grenoble INP-Pagora also offers a post-master's degree program that combines process engineering and biology to focus on valorizing biomasses (the Biorefinery program). As the number of programs continues to grow, the possibilities seem endless. The combination of healthcare and biology opens the door to a wide range of uses for technology and in particular, miniaturized technology.

Franz Bruckert

Professor at Grenoble INP-Phelma and director of the LMGP

Physics in the Service of Life Sciences

For many years, the connection between physics and life sciences has been an essential part of Grenoble's scientific and technological development. As a result, Grenoble inp has actively contributed to these fields.

"We have reached a point in biology where scientists must have multidisciplinary skills, in particular, knowledge of physics and mathematics." explains Franz Bruckert, a professor at Grenoble INP-Phelma and director of the LMGP*. For example, the field of physics offers powerful tools to observe life sciences (e.g. imaging equipment).

Thanks to knowledge of physics, we can unlock and understand biological characteristics such as self-organization. The use of three dimensional architectures allows us to simulate the mechanical properties of complex objects. Molecules can be used to modified the surface or core of these objects to create bioactive materials. At the same time, the highly organized structure of living systems provides scientists with inspiration for other fields.

Thanks to knowledge of physics, we can unlock and understand biological characteristics such as self-organization. The use of three dimensional architectures allows us to simulate the mechanical properties of complex objects. Molecules can be used to modified the surface or core of these objects to create bioactive materials. At the same time, the highly organized structure of living systems provides scientists with inspiration for other fields.

Healthcare: a Catalyst for Innovation

Healthcare has always encouraged scientists to push further. In Grenoble, biomedical engineering has become a strong economic strength for the region. The sector is support by high-level technological platforms and quality training dispensed by Grenoble INP and UGA.The MEDICALPS cluster works to unite the industry's various players. Grenoble INP laboratories work on creating miniaturized medical devices and bioactive implants (TIMC, Spintec, IMEP-LAHC, G2ELab, LMGP, etc.). Other projects aim to control the delivery of active ingredients or optimize biocompatibility for biomimicry materials (Labo Rhéologie and LMGP). The LEPMI and TIMC laboratories are looking into bio-assisted energy production and storage. The LGP2 is exploring the use of new molecules derived from biomasses.

Grenoble INP also provides expertise in the field of mathematics for life sciences. The GIPSA-lab has been working to create a model of complex phenomena. By using parallel analysis techniques for macromolecules (mass spectrometry and high-speed sequencing), researchers are able to create a global understanding of interactions on the cellular level. Given the complexity of analyzing and presenting the data collected using these techniques, they serve to highlight the challenges of tomorrow in the field of biology.

*Cited laboratories:

G2ELab: Electrical engineering laboratory

GIPSA-lab: Automatic images, sounds and signals laboratory

IMEP-Lahc: Institute for microelectronic electromagnetism and photonics, and laboratory for hyper-frequencies and characterization

LEPMI: Laboratory for electrochemistry and physiochemistry of materials and surfaces

LGP2: Paper engineering processes laboratory

LMGP: Materials and process engineering laboratory

LRP: Rheology and processes laboratory

Spintec: Spintronics and technological components

TIMC: Medical and complex engineering laboratory

The Power to Heal Bones

The Power to Heal Bones

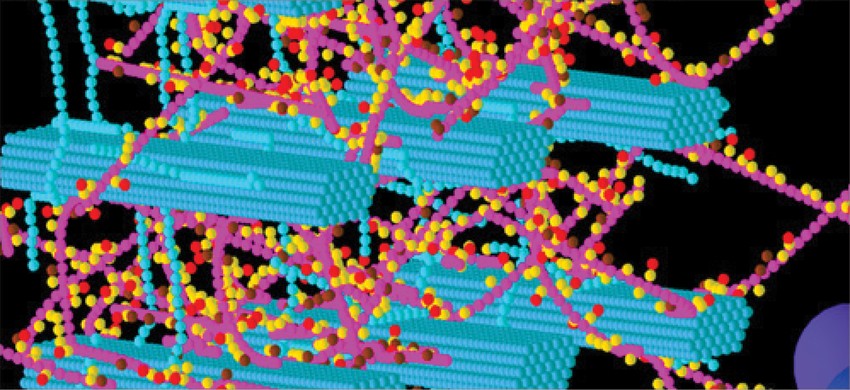

RCurrently, seriously broken or damaged bones can be fixed thanks to titanium implants for example. However, the future is one where doctors will be able to repair a bone even after a major traumatism. Catherine Picart, a professor at Grenoble INP-Phelma and a researcher at the LMGP, and her team are working on how to deliver bioactive bone morphogenetic proteins (BMPs) that can encourage bone and cartilage growth.

The challenge is to combine these bioactive molecules with the materials used during orthopedic surgery (e.g. titanium) or to reinforce vertebrates (e.g. polymers). Unfortunately, bioactive substances do not play well with the inert materials used for implants. To overcome this issue, Catherine Picart's team is working on the idea of using a thin polymer coating to cover implants with bioactive molecules. This biomimicry coating can not only be molded to cover an entire implant, but it also has the ability to trap BMPs and release them once the implant has been set.

In vitro laboratory tests and in vivo tests on small animals have demonstrated that this biomimicry coating can act as a catalyst for new bone growth. In addition, the coating can precisely control the dose of BMPs. The results of these findings could greatly improve our ability to heal bones.

Intelligent and Biocompatible SiC

Intelligent and Biocompatible SiC

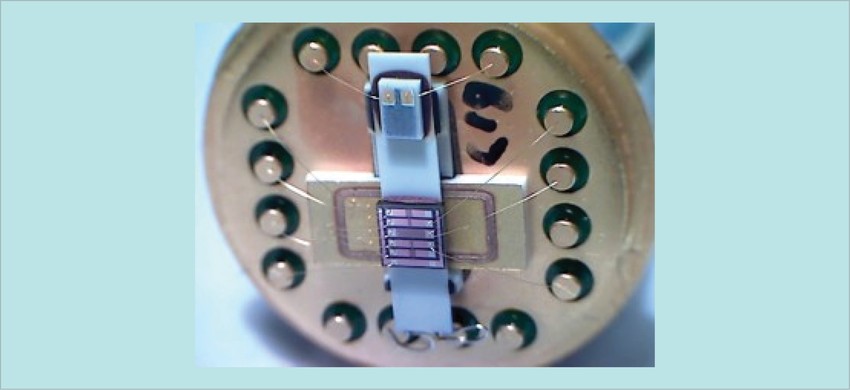

In addition to being an excellent semiconductor, silicon carbide (SiC) is both biocompatible and inert. These characteristics are ideal for creating biosensors used for in vivo monitoring of viral or bacterial growth. As a result, SiC nanowires could replace silicon nanowires which would add SiC's advantages to a nanowire's capacity for electronic detection.

Edwige Bano, who works at the IMEP-LACH, and Valérie Stambouli from the LMGP were the first to create SiC nanowire transistors capable of detecting specific molecules. "We used a sensor demonstrator to detect 20 DNA bases using complementary hybridization on an SiC nanowire. DNA hybridization modifies its electronic properties and this variation can be detected without the need for additional markers." explains Edwige Bano. As part of a European project proposal called SiC Nanowire, other possible uses are being explored, including the capacity for early detection of certain cancers or the detection of polluting particles in the environment.

The Secret Virtues of Hemicellulose

The Secret Virtues of Hemicellulose

Carbohydrates are very common in the pharmaceutical industry where they are used as active ingredients or excipients. Christine Chirat, a lecturer at Grenoble INP-Pagora and a researcher at the LGP2, has been working on valorizing the uses of hemicellulose, which is a complex polysaccharide found in wood cells. "Hemicellulose is usually used for energy purposes. However, it could be valorized if it was extracted before the Kraft process, which produces wood pulp for paper."

In partnership with professor Bertrand Toussaint from the The REx TIMC team, Chirat reviewed all of the carbohydrates that make up wood hemicellulose in order to discover potential therapeutic uses, in particular for intestinal disorders. "We set up a hydrolysis process to extract molecules of interest. We are currently testing the effects on bacteria in the digestive track. We have asked the CERMAV for help establishing a complete set of characteristics for promising molecules. This project is in part financed by the Labex TEC 21 and we are looking for additional funding." If the project is successful, it will highlight the advantages of molecules that are currently not on the market. In addition, these molecules can be produced in large numbers by paper manufacturers around the world, which would make them relatively accessible.

Improving the Stability of Therapeutic Proteins

Improving the Stability of Therapeutic Proteins

In partnership with Becton Dickinson and Eveon, the researcher and her team studied the behavior of insulin as an example. The goal was to analyze the absorption mechanism that controls a protein when it interacts with its container and the air. They also looked at how protein aggregates are formed.

By using tools taken from physics and mathematics, the researchers demonstrated that insulin prefers to aggregate when container, liquid and air converge (e.g. when there are air bubbles in a solution). "This highlights how important it is to consider the materials used for a container as well as the process used to load and administer a therapeutic protein." explains Marianne Weidenhaupt.

Growing Micro-Muscle Tissue

Growing Micro-Muscle Tissue

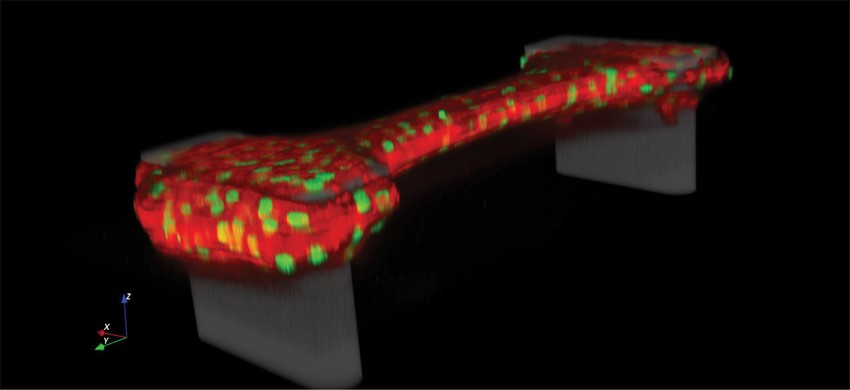

His invention is a plastic container that is several square centimeters big and contains 130 wells with 100 to 150 cells each. Within each well are two pillars made of flexible polymer. The rigidity and space between each pillar can be modified. "During cell growth, there is a certain amount of tension which can be recorded and analyzed according to various conditions." adds Thomas Boudou. This set up first allowed the researcher to understand the influence of rigidity on the healing process. As part of an ANR project, he was able to test the impact of mutations on muscle cell tonicity. Future work will make it possible to personalize therapeutic treatments according to a patient's needs by testing medicine on micro-muscles grown from the patient's own cells.

A Bio-Battery to Power Artificial Organs

A Bio-Battery to Power Artificial Organs

Bio-batteries are able to convert glucose found in bodily fluids into electricity. By doing so, they open the door to new avenues for powering medical devices such as pacemakers, artificial sphincters or insulin pumps. However, the performance of bio-batteries must still be improved before considering human testing. To answer this challenge, the TIMC joined forces with the LGP2 to produce flexible electrodes that can be rolled up. This increases their density in the battery and improves performance.

The research is supported by an ANR project. It has demonstrated the viability of printing processes such as ultrasonic sprays and photolithography to create homogeneous biocathodes. The project has served to optimize inks created with carbon nanotubes and surfactants. These inks were also used on a flexible hydrophobic substrate. By overcoming challenges in the printing process, the research produced active and flexible substrates.

The research is supported by an ANR project. It has demonstrated the viability of printing processes such as ultrasonic sprays and photolithography to create homogeneous biocathodes. The project has served to optimize inks created with carbon nanotubes and surfactants. These inks were also used on a flexible hydrophobic substrate. By overcoming challenges in the printing process, the research produced active and flexible substrates.

Complete Archives 2012-18

Newspaper

(PDF - env. 1,5 Mo)

Newsletter

(HTML)