Grenoble INP prepares the industry of the future!

Grenoble INP prepares the industry of the future!

The evolution towards the “industry of the future” or “industry 4.0” is bringing about major changes within organizations that impact everything from value chains to the organization of work processes. This transformation relies on digital and robotic technologies as well as new processes and materials. The goal is to optimize production processes, save energy and materials, improve quality and productivity, and meet the demands of consumers thanks to evermore personalized solutions. Since 2011, the National Research Agency has directed the G-SCOP laboratory to explore the industry of the future and identify key scientific challenges.

The evolution towards the “industry of the future” or “industry 4.0” is bringing about major changes within organizations that impact everything from value chains to the organization of work processes. This transformation relies on digital and robotic technologies as well as new processes and materials. The goal is to optimize production processes, save energy and materials, improve quality and productivity, and meet the demands of consumers thanks to evermore personalized solutions. Since 2011, the National Research Agency has directed the G-SCOP laboratory to explore the industry of the future and identify key scientific challenges.Grenoble INP currently has all the scientific skills required to overcome the challenges of developing the industry 4.0. Thanks to strong industry partnerships, the university is able to work on concrete problems. Its many cutting-edge technological platforms enable researchers to go from proof of concept to prototype development. The A2I project (Ateliers Intelligents de l’Industrie) unites five platforms to provide researchers, students and industry partners with an innovative environment as well as access to unique skillsets.

The research laboratories co-piloted by Grenoble INP in partnership with AIP-PRIMECA Dauphiné-Savoie cover the entire range of topics that will be impacted by the industry of the future. The G-SCOP laboratory explores the organization of industrial and production processes while the LCIS, LIG and GIPSA-lab cover robotics, simulation tools and the internet of things. Many other labs, such as SIMAP and G2Elab, are also involved in research on the industry 4.0. The university’s schools train engineers who can pilote complexe systems while continuing education programs support businesses by training employees in new fields and skills.

In collaboration with its industrial partners, Grenoble INP is moving forward to overcome the many challenges of the industry 4.0!

Valérie Rocchi

in charge of the innovation and industry 4.0 mission at G-SCOP and DRIVE

When industry meets the internet

Industry 4.0 or the factories of the future require a transformation in terms of industrial processes. Grenoble INP is carrying out research at all levels to help implement this transformation through new technology and innovation.

The world is undergoing a new industrial revolution to create the industry 4.0 (4.0 because it’s the fourth major industrial change the world has faced since the 18th century). The industry 4.0 began to emerge in the beginning of the 21st century. As explained by a report published in 2013 following the 2011 Hanovrede industrial trade show, this revolution coincides with the arrival of various technologies that enable the production and flow of big data.

As a result, the current industrial revolution can be summarized as the merger of internet and factories. Each link in the chain, including production, supply, tools and work environments, is being connected thanks to networks and the internet. It’s now possible to manage production systems in greater coordination with external demands from suppliers, clients and staff. Businesses have become hyper-connected. By optimizing these production tools, industrial partners will be able to increase production speed while lowering costs and reducing the use of resources.

The potential of a new industry

Most of the digital tools required for a factory of the future are currently being explored in research projects carried out by laboratories co-piloted by Grenoble INP. Examples include: simulation (G-SCOP, LIG,...) sensors (LCIS, IMEP-LAHC), virtual and augmented reality (G-SCOP), additive manufacturing (G-SCOP, AIP-PRIMECA Dauphiné-Savoie), autonomous robots (LIG, GIPSA-lab), big data and analytics (LIG,...), Internet of Things (LIG, LCIS), cloud computing (LIG), and cybersecurity (Verimag).

The G-SCOP laboratory is working on the entire life cycle from design to the end of a product’s life cycle. Reliability and sustainability are going to be key factors for any factory of the future.

By completely reorganizing production methods and increasing the importance of networks, next generation factories could kickstart the European industry. Such an evolution can increase competitivity and help European industrial actors face off against global competitors and low-cost competitors in developing countries.

This evolution will enable connected machines to produce in a “smart” manner. Production will become more flexible and adapt to real-time customer demands. Connected systems also provide greater traceability. “This will enable the implementation of security measures throughout the manufacturing process, which will facilitate product recalls,” adds Valérie Rocchie. In addition, connected machines can be coordinated to optimize production according to the cost and availability of energy.

By interacting with the internet, production tools can anticipate maintenance issues. Machines will be able to call upon the right specialist to fix a problem or install an update. In partnership with STMicroelectronics, G-SCOP has set up a system to control production risks by constantly anticipating and analyzing errors. The Crolles 300 production site now operates in Industry 4.0 mode with a wide diversity of products and numerous operations per product.

This system of connected machines creates a very large flow of data that covers everything from production to maintenance and production design. Quality control can now be regulated thanks to machine and product parameters. Data drawn from production lines can be used for more than curative actions (fixing a mistake). The goal is to anticipate problems and maintenance needs before they become critical.

“We use systems and algorithms developed by ProbaYes, a business specialized in decision-making software using bayesian networks. We’ve adapted them to meet the needs of STMicroelectronics and analyze potential issues with their production machines. The system then provides diagnostics and possible action plans. We also implemented training programs to ensure employees can use these new systems correctly,” explains Michel Tollenaere, a professor at Grenoble INP (G-SCOP).

The evolution towards the factory of the future relies on digital technology and automating certain processes. As a result, it’s changing the relationship between man and machine. “These factories will not only improve security and health, but also enable employees to work on tasks that have greater added-value.”

The real disruptive change will come from smart machines that will interact and react to situations in real-time without human interference. Such systems are currently under developed.

DRIVE : Direction Recherche Innovation Valorisation Europe

GIPSA-lab : Grenoble Images Parole Signal Automatique

G-SCOP : Sciences pour la Conception, l'Optimisation et la Production

IMEP-LAHC : Institut de Microélectronique Electromagnétisme et Photonique et le Laboratoire d'Hyperfréquences et de Caractérisation

LCIS : Laboratoire de Conception et d'Intégration des Systèmes

LIG : Laboratoire d'Informatique de Grenoble

SIMAP : Science et Ingénierie des Matériaux et Procédés

The G-SCOP laboratory is working on the entire life cycle from design to the end of a product’s life cycle. Reliability and sustainability are going to be key factors for any factory of the future.

By completely reorganizing production methods and increasing the importance of networks, next generation factories could kickstart the European industry. Such an evolution can increase competitivity and help European industrial actors face off against global competitors and low-cost competitors in developing countries.

This evolution will enable connected machines to produce in a “smart” manner. Production will become more flexible and adapt to real-time customer demands. Connected systems also provide greater traceability. “This will enable the implementation of security measures throughout the manufacturing process, which will facilitate product recalls,” adds Valérie Rocchie. In addition, connected machines can be coordinated to optimize production according to the cost and availability of energy.

By interacting with the internet, production tools can anticipate maintenance issues. Machines will be able to call upon the right specialist to fix a problem or install an update. In partnership with STMicroelectronics, G-SCOP has set up a system to control production risks by constantly anticipating and analyzing errors. The Crolles 300 production site now operates in Industry 4.0 mode with a wide diversity of products and numerous operations per product.

This system of connected machines creates a very large flow of data that covers everything from production to maintenance and production design. Quality control can now be regulated thanks to machine and product parameters. Data drawn from production lines can be used for more than curative actions (fixing a mistake). The goal is to anticipate problems and maintenance needs before they become critical.

“We use systems and algorithms developed by ProbaYes, a business specialized in decision-making software using bayesian networks. We’ve adapted them to meet the needs of STMicroelectronics and analyze potential issues with their production machines. The system then provides diagnostics and possible action plans. We also implemented training programs to ensure employees can use these new systems correctly,” explains Michel Tollenaere, a professor at Grenoble INP (G-SCOP).

The evolution towards the factory of the future relies on digital technology and automating certain processes. As a result, it’s changing the relationship between man and machine. “These factories will not only improve security and health, but also enable employees to work on tasks that have greater added-value.”

The real disruptive change will come from smart machines that will interact and react to situations in real-time without human interference. Such systems are currently under developed.

DRIVE : Direction Recherche Innovation Valorisation Europe

GIPSA-lab : Grenoble Images Parole Signal Automatique

G-SCOP : Sciences pour la Conception, l'Optimisation et la Production

IMEP-LAHC : Institut de Microélectronique Electromagnétisme et Photonique et le Laboratoire d'Hyperfréquences et de Caractérisation

LCIS : Laboratoire de Conception et d'Intégration des Systèmes

LIG : Laboratoire d'Informatique de Grenoble

SIMAP : Science et Ingénierie des Matériaux et Procédés

Mastering the 4.0 supply chain

The industry of the future requires better visibility in terms of logistics. Karine Samuel is a researcher at the CERAG (a Grenoble INP partner) and a professor at various Grenoble INP schools. For the past several months, she has been working on a project in collaboration with several industrial actors in the aeronautics industry. The goal is to move towards 4.0 supply chains.

Airbus launched the project idea in response to the fact it could not see further than its first circle of suppliers. As a result, the aeronautics giant wanted to capitalize on the data produced by its subcontractors in order to improve visibility. “The goal is to identify and communicate pertinent data in order to create a system that can quickly anticipate and react to risks in terms of supply and management,” explains Karine Samuel.

To achieve this result, what changes must factories implement? How can businesses benefit from this information system? How can you organize and analyze such data? These questions and many more are the focus of this project. “In the end, the answers to these questions will probably be implemented directly in the design process when imagining logistics and production. This will be particularly important to meet growing demands for airplanes and the need to manage several projects at once,” adds Karine Samuel. “The key to success lies in mastering supply chains in a way that integrates new technology, meets cost requirements and provides a sustainable and reliable solution.” In the future, the research project could be expanded to cover other sectors.

G-SCOP collaborates on several international projects

Grenoble INP is part of the ANR Open! project. The goal of the project is to expand open source beyond software in order to include physical objects.

“There has been widespread development of low-cost tools such as 3D printing and laser cutting systems. This has simplified the creation of prototypes and therefore enabled open source design,” explains Jean-François Boujut, a researcher at G-SCOP and a professor at Grenoble INP. “The idea is to promote an open source community-oriented approach to product design. Our goal is to help organize and develop this community by connecting creators, investors and users.” The idea was first launched in 2007 and G-SCOP has had the chance to participate in what has proven to be a pioneering initiative.

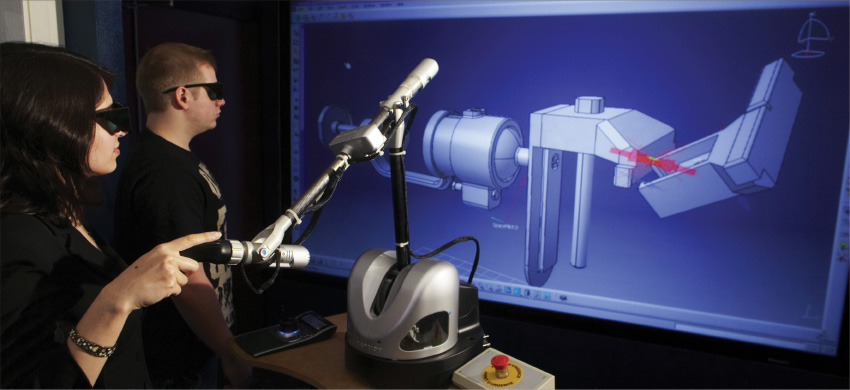

The laboratory is also a partner in a European project for virtual and augmented reality innovation. The SPARK project aims to: “Develop an augmented reality platform that will enable collaboration on a physical object for innovation purposes. It’s mostly aimed at SMEs.” Started in 2016, this three-year European project unites three academic partners and four industrial partners.

G-SCOP contributes to the project by working on the integration of augmented and mixed reality solutions to visualize product design during innovation phases. The laboratory is also working on solutions for testing and validation, which could then be adapted to experimental and controlled work environments.

Cutting-edge equipment at Grenoble INP

The additive manufacturing platform at AIP-PRIMECA Dauphiné-Savoie and the G-SCOP augmented and virtual reality platform are two examples of Grenoble INP’s wide range of cutting-edge technological platforms that support the development of proof of concepts and prototypes.

In 2013, Grenoble INP set up the first French academic Electron Beam Melting machine. The machine enables users to merge metallic materials using an electron beam. As a result, it’s possible to create complex multifunctional metallic objects layer by layer.

The augmented and virtual reality platform at G-SCOP also recently added a mini-CAVE. The innovative added value of this equipment is the fact it enables a totally immersive and virtual environment representative of a standard building. It’s probably the smallest CAVE in the world (parallelepiped of 80”). It provides researchers, students and SMEs with a fully immersive 3D solution.

Newspaper

(PDF - env. 1,5 Mo)

Grenoble INP prepares the industry of the future!

Grenoble INP prepares the industry of the future! When industry meets the internet

When industry meets the internet Mastering the 4.0 supply chain

Mastering the 4.0 supply chain G-SCOP collaborates on several international projects

G-SCOP collaborates on several international projects Cutting-edge equipment at Grenoble INP

Cutting-edge equipment at Grenoble INP