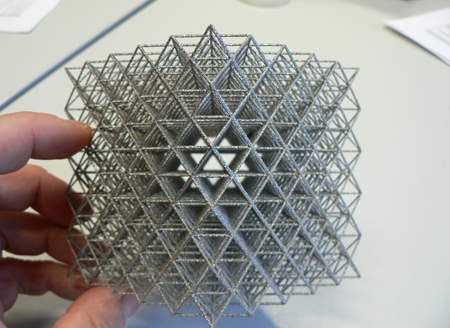

The eco-design of architectured materials is crucial. Accordingly, all direct manufacturing processes whose machining stages can be eliminated are interesting strategies and in this respect the researchers in Grenoble have a major advantage: an EBM (Electron Beam Melting) additive manufacturing machine. This is the first machine of its type installed on a university site in France. It is able to manufacture metal parts layer by layer and allows considerable freedom for design. As a result, it is therefore very well suited to the development of architectured materials. Jean-Jacques Blandin explained: "these processes enable the transition from a “ready-made" product to a "tailor-made" product directly based on user needs. Moreover, as they generate almost no waste, they are emblematic of an eco-efficiency approach in the materials field”. Some of these advantages were already procured by the sintering processes, a technique that Grenoble INP also counts amongst its list of expertise, and which is used for the controlled production of metallic and ceramic materials. The recycling processes of end-of-life parts should also be given special attention and the strong ties established between Grenoble INP and RECUPYL, a company that was created at Grenoble INP, are a real asset in this area.

Grenoble INP’s positioning and recognition in the field of architectured materials are behind the decision made by Grenoble to give priority to this theme. This recognition also stems from the site’s proximity to the major instruments and in particular, synchrotron, with which it enjoys a decade-long partnership on X-ray tomography of architectured materials. Network-based research on this theme is also carried out in the Rhône-Alpes region notably through the establishment of a scientific interest grouping on architectured materials between Grenoble INP and INSA Lyon.

Presently, the Rhône-Alpes region boasts international and national recognition as a key player in these fields of architecturation of materials both in terms of volume and surface area. A project to create a Centre for Eco-design of Architectured Materials (EcoMarch) was initiated within the framework of the next State-Region Planning Contract (CPER), with the goal of reinforcing this position and focusing more explicitly on the integration of eco-efficiency aspects.

SUMMARY

- Architectured materials: paving the way for eco-design?

- Grenoble INP, recognised expertise in materials

- Enhanced environmentally-friendly processes

- Tomography: a journey to the heart of the matter

- Additive manufacturing revolutionises materials

- Bio-sourced materials are the way to the future

- The EcoMarch project

- From laboratories to start-ups

Grenoble IN'Press

Contact

- Vice-présidente Recherche et du Conseil Scientifique

Lorena Anghel - Vice-présidente Innovation et Relations entreprises

Gaëlle Calvary - Directeur de la DRIVE

Cédric Di Tofano Orlando

Tél. 04 76 57 43 16 - Annuaire