For many years now, the Materials and Processes field has been a key area in Grenoble. According to the latest international rankings, Grenoble INP is the top French University and ranks amongst the world’s best in the materials sector. Several Carnot Institute or LABEX (including the CEMAM, Centre of Excellence of Multifunctional Architectured Materials) projects, where research on materials plays an essential role, have been selected within the framework of the Investments for the Future (Investissements d’Avenir) and are a further reflection of Grenoble INP’s excellence .

Materials have always played a necessary and essential role in transforming an idea into an object. They are therefore a key sector of the economy. Materials and their related manufacturing processes represent a major strategic focus in the Rhône-Alpes region, backed by a highly dynamic industrial sector composed of major corporations as well as a network of medium-sized companies which are all federated by several competitive clusters including VIAMECA. In this context, the development of environmentally-friendly materials (notion of eco-efficiency) is an issue of fundamental importance for the years to come.

Eco-efficiency in the materials field can be broken down into several areas: the selection of the type of materials, reducing the quantity of material to fulfil a function, the development of environmentally-friendly manufacturing processes and the end-of-life recyclability.

The Grenoble Alpes University (UGA) is particularly well-equipped to rise to these new challenges. As a matter of fact, the development of bio-sourced materials, in conjunction with Carnot Institute Polynat in particular, is one initial option for addressing these challenges. UGA has gained both national and international recognition for its expertise in this field. Alongside bio-sourced materials, the development of “architectured" materials is also a very promising strategy in terms of eco-efficiency. As Jean-Jacques Blandin, a researcher at the SIMAP laboratory, points out, "an architectured material is optimised at an intermediary scale between that of the microstructure and that of the part. This gives access to hitherto inaccessible material property combinations with the added bonus of optimum material savings". Architectured materials such as cellular, sandwich, laminate or gradient materials can therefore provide effective solutions to several eco-efficiency issues insofar as architecturation enables material savings through optimal distribution while providing real multifunctionality. These new materials have already been integrated into the automobile, aerospace, energy, construction, and biomedical sectors, to name a few.

SUMMARY

- Architectured materials: paving the way for eco-design?

- Grenoble INP, recognised expertise in materials

- Enhanced environmentally-friendly processes

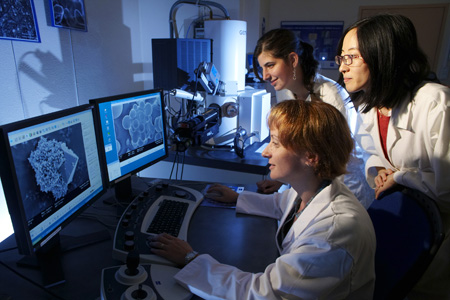

- Tomography: a journey to the heart of the matter

- Additive manufacturing revolutionises materials

- Bio-sourced materials are the way to the future

- The EcoMarch project

- From laboratories to start-ups

Grenoble IN'Press

Contact

- Vice-présidente Recherche et du Conseil Scientifique

Lorena Anghel - Vice-présidente Innovation et Relations entreprises

Gaëlle Calvary - Directeur de la DRIVE

Cédric Di Tofano Orlando

Tél. 04 76 57 43 16 - Annuaire